About Us

Product Category

Hot Products

Hanma High Speed Open-Width Double Knitting Machine is developed on the basis of Double machine and possesses the characteristics of the double machine.

Double Jersey Rib Interlock Circular Knitting Machine install with two tracks CAMs on the dial plate and four tracks CAMs in the cylinder, through adjusting

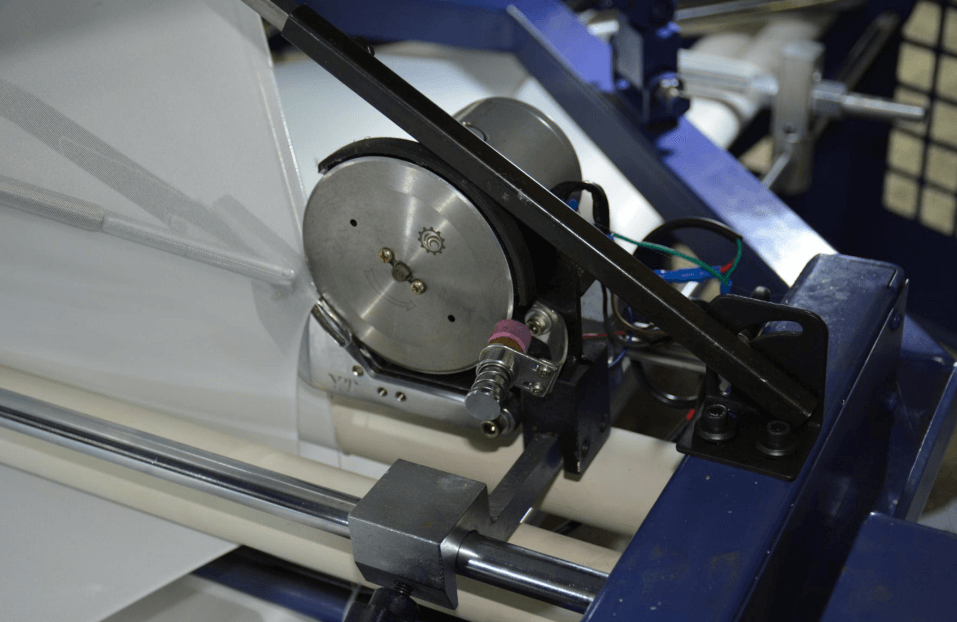

The major advantages of the machine: shearing can be done in the machine synchronously, to reduce the losses of materials and save the cost.

The machine has the characteristics of frequency control, transmission speed adjustment, failing cloth in take-up cloth mode

It adopts four-track cam design of closed type with Draw-down cam, Tuck cam, Floating threads cam. Central total lift can easily

Complete and sophisticated chestnut process design can be equipped with sinkers in different specifications.

HIGH LEG DOUBLE JERSEY OPEN WIDTH KNITTING MACHINE

Classification:

Double Jersey Circular Knitting Machine

Summary:

The company introduces international advanced technology and production inspection equipment. The development and design of products all adopt international advanced three-dimensional (3D) three-dimensional design.

Tel:

Tel:

- Presentation

- Specification

- Shipping

- Detail

- Equipment

- Features

- Fabric

-

- Commodity name: HIGH LEG DOUBLE JERSEY OPEN WIDTH KNITTING MACHINE

Hanma High Speed Open-Width Double Knitting Machine is developed on the basis of Double machine and possesses the characteristics of the double machine.

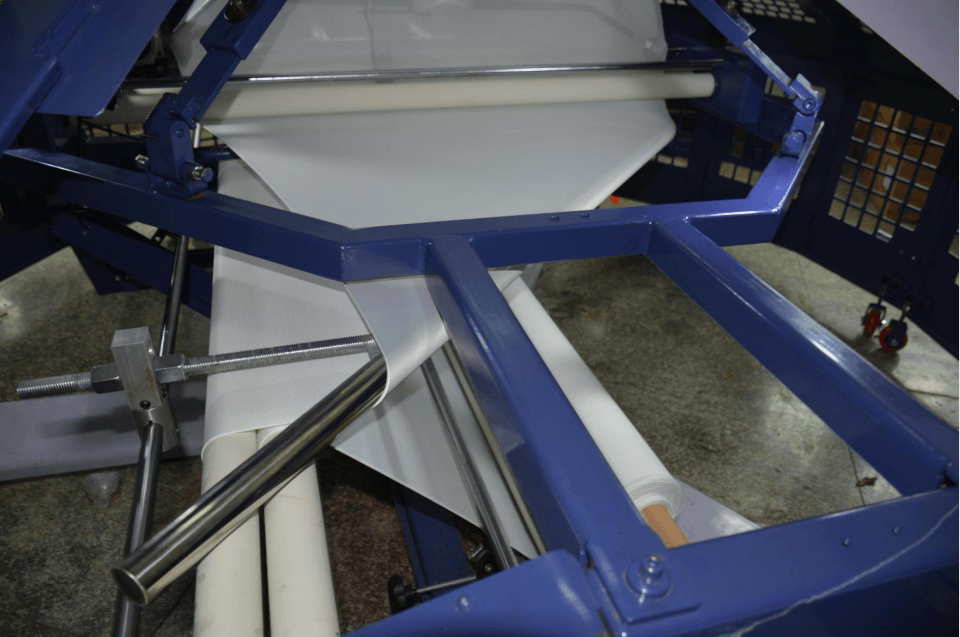

Hanma High Speed Open-Width Double Knitting Machine is developed on the basis of Double machine and possesses the characteristics of the double machine. Gray Fabric can be cut without crease and wastage.

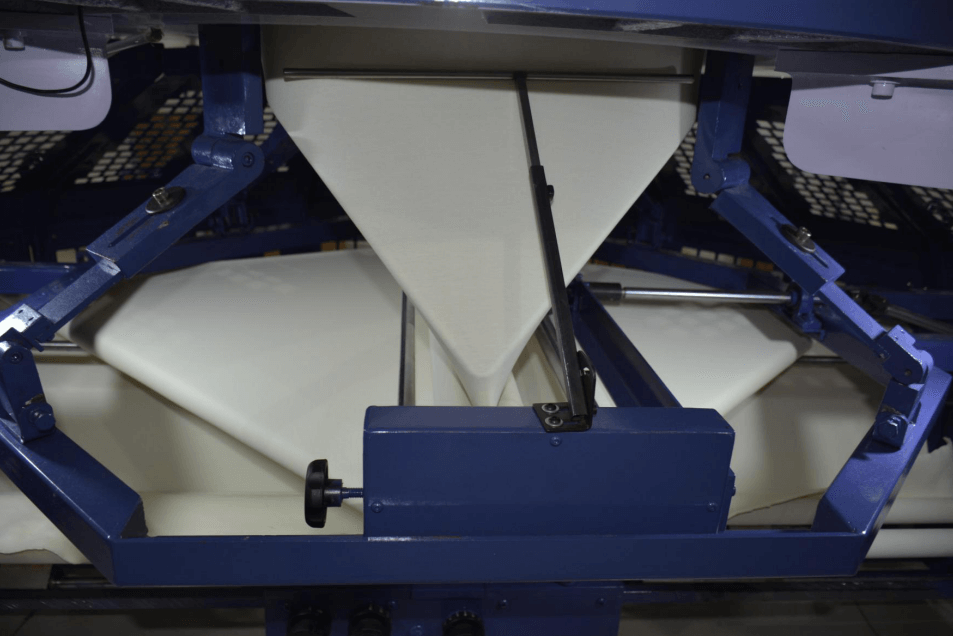

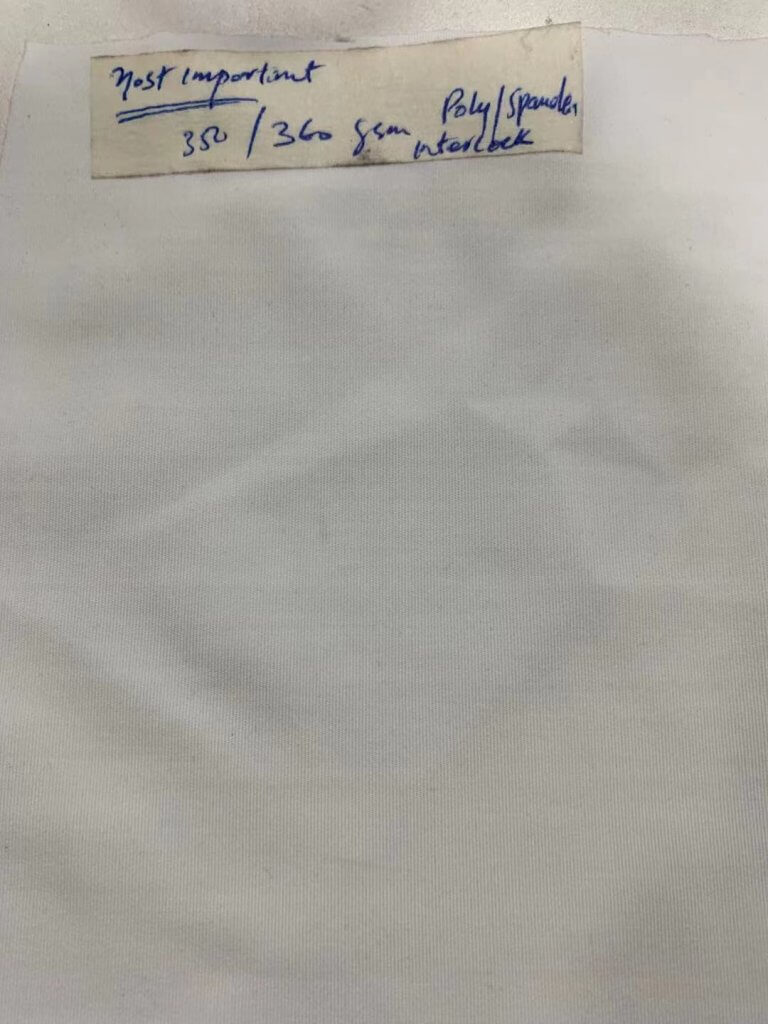

The upper and lower cam of this machine is a closed track and wide needle heel design, with Drawdown cam * Tuck cam. Floating threads cam, able to simply weave and make cam changes, it can weave tissue cloth with different styles and high quality, such as elastic health cloth ( polyester health cloth ), twill, air layer, interlayer pads, bubble cloth, double mesh, mercerized cotton and a variety of color textures. The fabric of senior men’s and women’s fashion such as elastic double-surface cloth can be weaved equipped with a spandex OP device. Human design enables needle cylinders and needle plates to be more simple and quick, to adapt to the changing market demands.

Combining the characteristics of double jersey and crease-free for cloths from knitting machines. High fabric output, equipped with a large diameter cylinder and high-speed motor; automatic cutting system to ensure unnecessary fabric loss. -

Double jersey machines have two sets of needles; one on dial and as well as on cylinder. There are no sinkers in double jersey machines.

This double arrangement of needles allows the fabric to be manufactured which is twice as thick as the single jersey fabric, known as double jersey fabric

Diameter 24″-42″

Gauge 15G-40G

Feeder 60F-102F

Speed 16-30r/min

Power 5.5HP -

Condition: New Product Type:fabric Type:Circular Production Capacity:250-750kg Place of Origin: Fujian China

(Mainland)Brand Name:HANMA

(circular knitting machine)Model Number:HM-DF4

(circular knitting machine)Power(W):5.5kw

(circular knitting machine)Knitting Style: knitted Knitting Method: Double Computerized: No Weight:2.5TON Dimension(L*W*H):2.35*2.28*2.28M After-sales Service Provided:Engineers

available to service machinery overseasspeed:0-30RPM Certificate: CE machine type: double jersey turn way: anticlockwise fabric function:sports garment

-

No Description Supplier Brand Quantity 1 Insert flake type cylinde&dlar(Germany metal) Hanma China 1 unit 2 Needles Groz-beckert Germany 1 Set 3 Positive storage yarn feeders Hanma China 1 Unit 4 Oiling lubricator Hongsheng China 1 Set 5 Yarn Creel Hanma China 1 Set 6 One way take-down device Hanma China 1 Set 7 Invertor Sunyue China 1 Set 8 Fabric Spreader equipment Hanma China 1 Set 9 Cams Japan 1 Set 10 Digital indicator control panel Hanma China 1 set 11 Automatic dust fans with blower equipment. San song China 1 set 12 Radar type round 360’ clear dust equipment San song China 1 set 13 Spare tools 14 Operation manual for invertor & controller panel 15 Extra Spare parts : (a) 100pcs needles (b)Feeders 1pcs (c)Air blower gun 1 set (d)Fuse 4pcs (e) Yarn carrier 1pcs (f)Needle oil 1 liter -

Following the gear design without unfolding the fabric, allows easy rolling up of cloth. Its safety shutdown device functions when the cloth is not cut completely. The cloth collecting stick can roll up cloth automatically, to process cloth of diverse sizes, even those which are too small to strain. The cloth-cutting machine is equipped with a roller speed adjustment device, guaranteeing a uniform and stable knitting tightness for the fabric.

In general, the rate of production in knitting is much higher with less preparatory processes than weaving. Circular weft knitting machines offer the greatest potential for high speed production, because knitting can take place continuously in the same direction of yarn feed, and the rotary motion minimizes problems of vibration and wear and tear at high speed. In most latch-needle circular machines, knitting of yarn at a single feeder occupies a relatively small part of the circumference of the needle circle and the simplest way of increasing production is therefore to incorporate additional feeder around the circumference, so that for each revolution of the machine more than one course is knitted at a time. The number of feeder that can be accommodated depends on the gauge and diameter of the machine and the number of needle spaces taken by the cam system at each feeder. With present machines each feeder may occupy one inch of circumference, the limit being imposed by the cam angles. The flat bed weft knitting machines are in general simple but low productive. The design capacity of these machines has also passed through revolutionary changes. With the help of CAD and CAM, seamless garments are manufactured in flat bed weft knitting machines. The warp knitting machines are more versatile but those are complicated and costly.

Keywords:

Related Products

Customer Message

If you have any questions, you can leave us a message directly

Zhenfu Knitting Machine Co., Ltd. Shishi

Email: lin@china-hanma.com

lois@china-hanma.com

Add: No. 18 Xinfu Road, High-tech Zone, Xiangzhi Town, Shishi City, Quanzhou City, Fujian Province, China

Copyright©2024 Zhenfu Knitting Machine Co., Ltd. Shishi SEO Privacy Policy

Powered by 300.cn